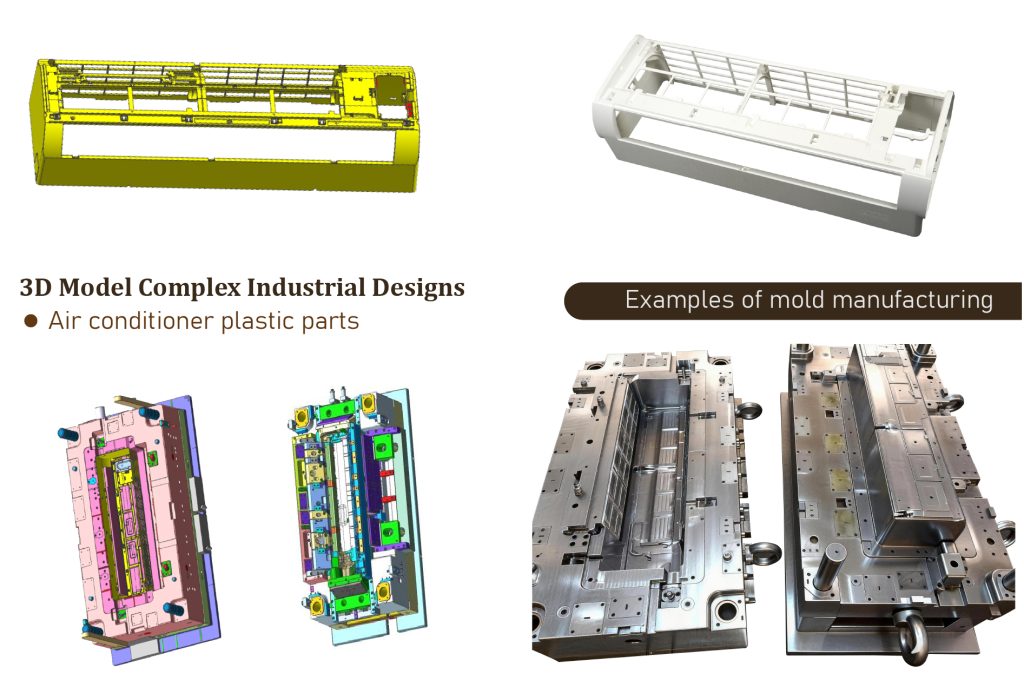

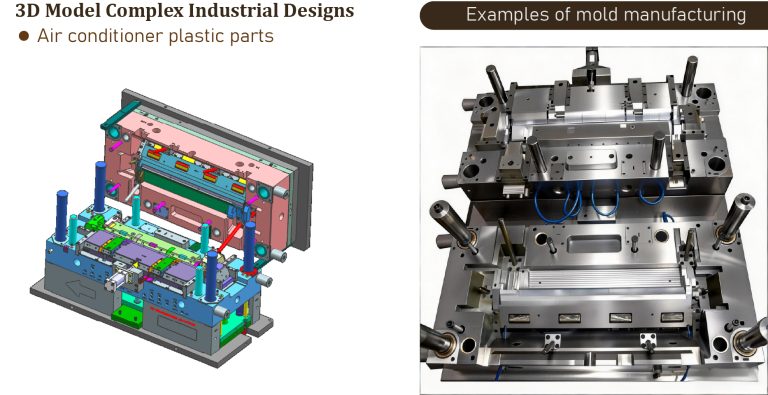

Strong mold design and development capabilities

· High-speed 5-Axis CNC machine center

· Electrical Discharge Machining

· High-speed milling machine

Company Introduction

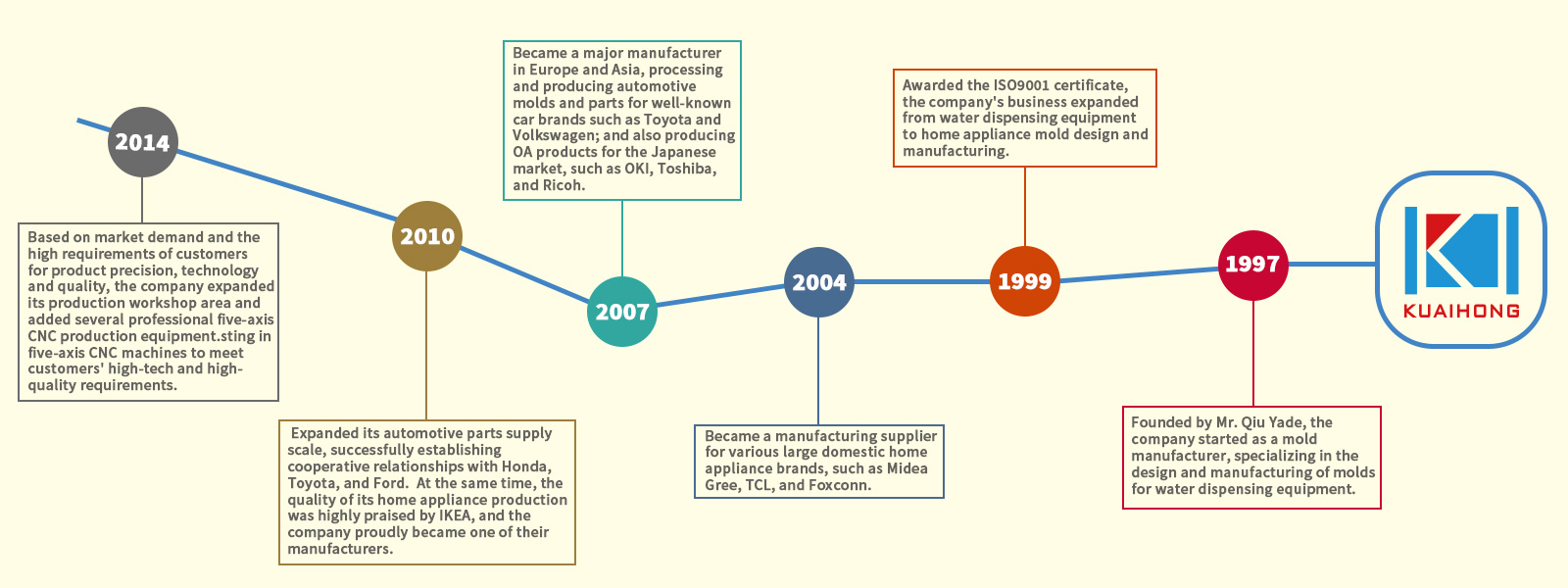

Nearly 30Yrs Manufacturing History

Shenzhen Kuaihong Industrial Co., Ltd. Was Founded in 1997, which is a plastic manufacturer integrating design, research and development, manufacturing, and trade. We have nearly years of experience in the plastic products industry.

Our greatest advantage is providing customers with one-stop, customized product manufacturing services. Our professional foreign trade team is familiar with the market standards and trade processes of multiple countries. Through flexible cooperation models (such as RTS/CUSTOMIZATION) and support for fast and convenient logistics and customs clearance procedures, we make import and export trade more efficient and customer-friendly.

We are an excellent supplier of Wal-Mart, IKEA, Midea, Gree, BYD, Toyota and other big brands, with more than 29 years of experience in houseware product design and development, providing one-stop service of product design, mold opening, injection molding and assembly.

Our Advantage

Customized Services

We including a R&D team of 20 designers and structural engineers.

We could follow customer’s requirement to make customized manufacturing, 3D drawing R&D, QC, assembling, logo printing, surface process, plastic mold and hardware mold.

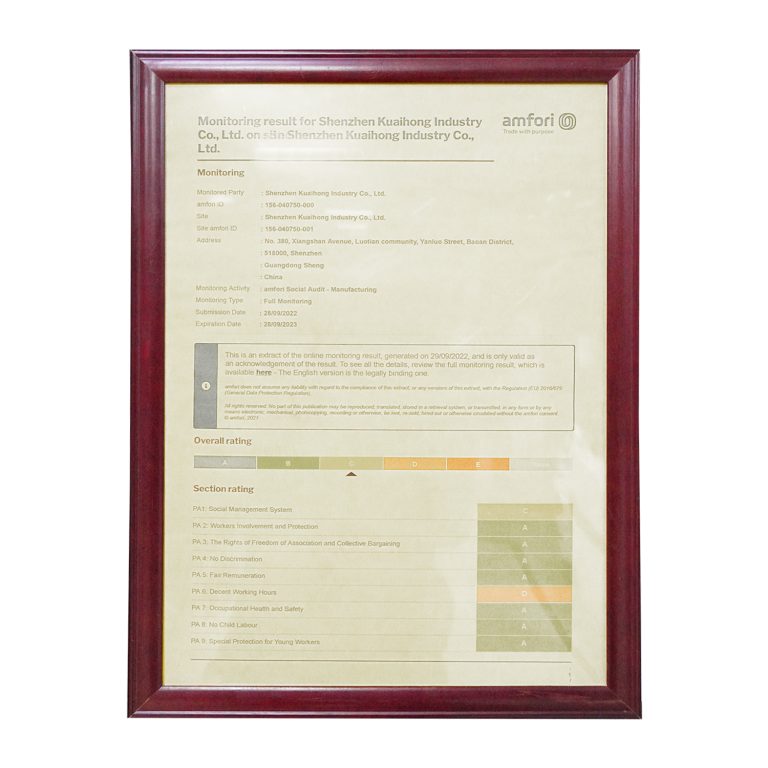

Quality System

Stringent quality control ensures product stability and reliability

Quality assurance is one of the key success factors for Kuaihong Industrial Co., Ltd. We are certified to international standards such as ISO9001, and all our products are manufactured according to RoHS standards. From raw material procurement to finished product shipment, we have established a comprehensive quality control process encompassing IQC, IPQC, FOC, and OQC. Every production process undergoes rigorous quality inspection, combined with advanced testing equipment, to provide our customers with reliable products.

IQC

We conduct rigorous inspections on raw materials and components to ensure that all materials meet quality standards and technical requirements.

IPQC

Multiple inspection points are set up throughout the production process to monitor production quality in real time and identify and resolve problems promptly.

FQC

All finished products coming off the production line must undergo "rigorous scrutiny" by FQC (Final Quality Control). Only products that pass the FQC inspection are considered truly qualified.

OQC

Before shipment, the finished products undergo a comprehensive inspection, including appearance, dimensions, and functions, to ensure that the products meet customer requirements.

- Our factory equipped with 160 professional machines (CNC, injection molding machines, etc.). We possess comprehensive capabilities in high-precision mold development, manufacturing, logistics, and after-sales service. With over 150 employees, we can complete mold manufacturing and begin injection molding production within 20 days. The monthly production capacity for a single product exceeds 500,000 units.

Factory Show

Area: 25,000 square meters

Our company's self-built factory covers an area of 25,000 square meters.

Number of employees ≥ 150

With over 150 employees, including a R&D team of 20 designers and structural engineers.

machines:160 professional devices

We have 160 pieces of production equipment, including high-speed five-axis CNC machining centers, electrical discharge machining machines, high-speed milling machines, and Pioneer 600Ⅱ height measuring instruments.

Super production capacity

we can complete mold manufacturing and begin injection molding production within 20 days.The average monthly production capacity of a single product is more than 500,000 pcs.

Development History

Certificate Honors

We are an excellent supplier of Wal-Mart, IKEA, Midea, Gree, BYD, Toyota and other big brands, with more than 20 years of experience in houseware product design and development.